A joke comes to mind when thinking of speed. What did the snail say that was riding on a turtle’s back? WWWEEEEEEEEEEE!!!! The point of the joke is that everything is relative, including the concept of speed. When is “fast-enough” really “fast-enough”? In the construction world, generally, quicker is better. Consequently, completing a project in a shorter time than “normal” is advantageous to the owner.

However, a couple of problems pop up when trying to speed up construction. These are safety and quality. Imagine if the superintendent instructs his equipment drivers to double their speed and tells the laborers to run instead of walking between tasks. People will get hurt, and the construction quality will go down. One must be reasonable when making decisions to increase speed.

It is no different in the precast world vs. on-site construction. Safety and quality must be a priority above speed. In fact, in Tindall’s culture, safety is the number one priority. Tindall dedicates a tremendous amount of time, effort, and expense to safety training, inspections, modifying work procedures, providing the correct personal safety equipment, etc.

So, how does using precast concrete construction increase the overall speed of the project while maintaining a high level of safety and quality?

Project Management/Planning

Managing a project is not unique to precast concrete construction. Project management has been around since ancient times. Indeed, planning was needed to build the pyramids and the Roman Colosseum. One of the tools used by project management is called the Critical Path Method (CPM). It was developed in the 1950s and first widely used by DuPont for planning new construction and maintenance shutdowns. CPM put the project thought process “down on paper” to clarify the needed concepts for more efficient project planning. Even before the development of CPM, a chart for outlining project tasks was developed by Henry Gantt in the early 1900s. This chart is commonly known as a Gantt chart and is used in various forms in commercially available project planning software.

The basic concept is to think through an entire project, make a list of all activities, estimate the required time to complete each activity, and plan accordingly. If one task cannot start until another is completed, then that enters the plan. For example, if the dinner’s main course is not prepared, then it cannot be consumed. However, the dessert course can be prepared while the family eats the main course. When they finish the main course, the dessert can be served and eaten. This is a simple example of overlapping tasks. The dessert preparation and the eating are taking place at the same time.

To take this analogy a step further, imagine a 12-course Chinese dinner. If it is decided to wait until all twelve courses are fully prepared before serving, then the dishes must be stored and kept hot until they are served. This is neither efficient nor practical. There is not enough counter space to store all the dishes, nor is it easy to keep them at serving temperature.

It is no different when planning a construction project. Notice two words that popped up in the Chinese meal analogy – efficient and practical. Let us examine efficiency. A common definition is that being efficient means that a process can produce the desired results with a minimum waste of time and materials. Practical indicates a process that is capable of being used – in other words, it is useful. Indeed, these two words apply to all types of construction, whether the type is steel, wood, cast-in-place concrete (CIP), or precast concrete.

Of the types of construction mentioned above, the planning for wood, steel, and precast concrete is similar when compared to CIP construction. Why is this? Well, wood, steel, and precast concrete are prefabricated at one location and then transported to the site for installation. In contrast, CIP work is all done at the site. As the name implies, it is cast-in-place. Prefabrication allows for more tasks that can be done simultaneously or overlapped. This will result in a reduction in the overall time needed to complete the project.

How Speed is Accomplished in Precast Projects

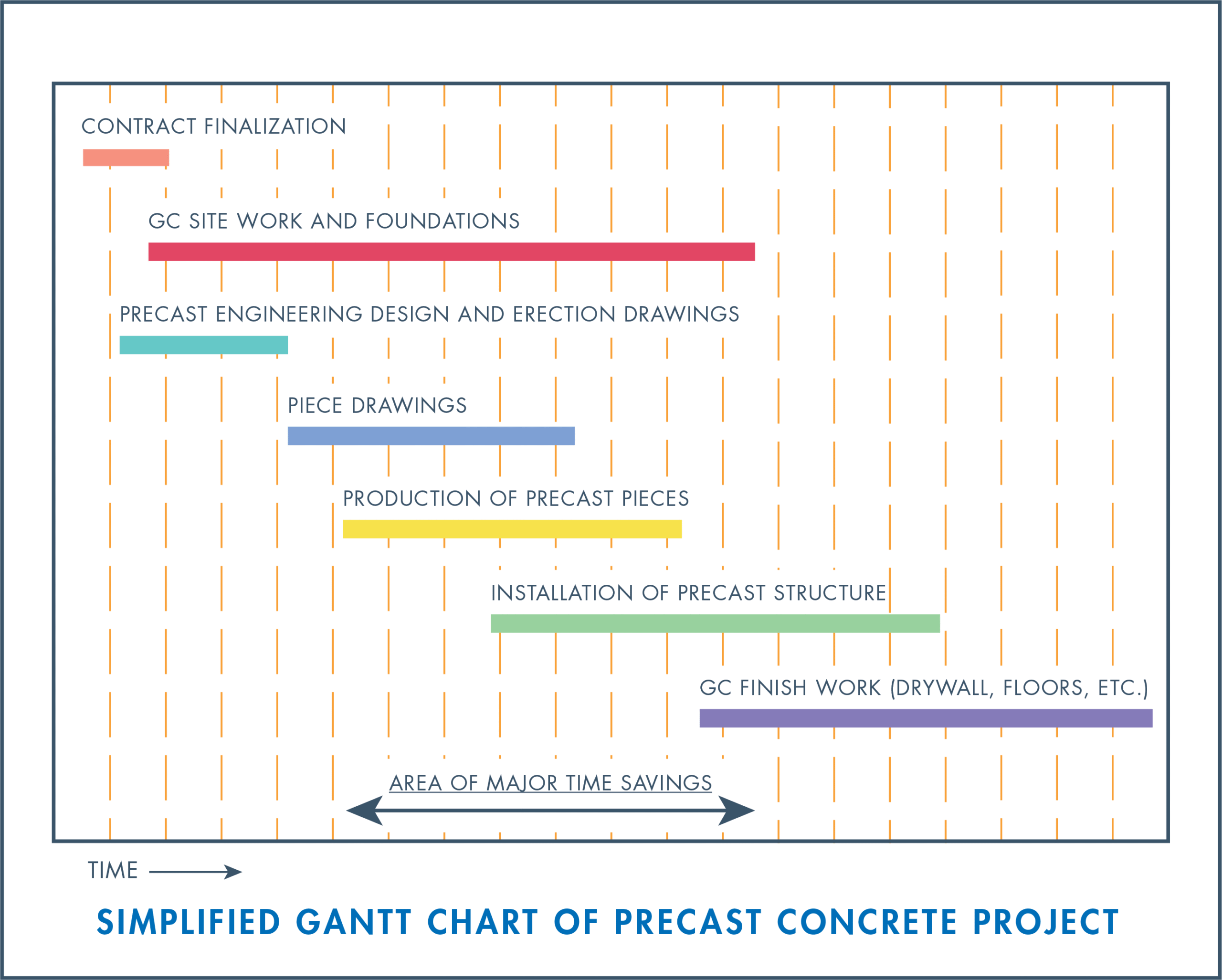

As previously stated, when a project incorporates prefabricated products, there are overlapping tasks created, which allow for time savings. A typical precast concrete project schedule is described below. Opportunities for time savings are identified in this example.

The basic steps/tasks of a precast project are:

- Owner’s design professionals develop bid and contract drawings and specifications. Note: bringing Tindall’s professional team in at this stage will result in the most efficient design/construction process and will result in the most satisfying project.

- Tindall and the General Contractor (GC) work out the final contract terms, and a contract is signed.

- When the contract is finalized, a Scope of Work and Project Schedule are determined.

- At this time, the Tindall project management team meets internally with engineering, production, purchasing, shipping, field operations, etc., to hash out basic durations of the tasks associated with each discipline. For example, to prepare for fabrication of the individual precast members, engineering needs to do structural calculations, prepare installation drawings (commonly called erection drawings), and then submit them to the outside design professionals (GC, architect, engineers) for review and approval. Upon receiving approval, engineering can then start preparing detailed drawings to produce each piece (often called shop cards or production tickets).

- While engineering is “doing their thing,” work at the site has already started. Usually, this is the general site grading, location of drainage piping, and the beginning of foundation excavation. This is an example of overlapping tasks.

- The GC’s work at the site continues while the shop cards are prepared, and production of precast pieces is started.

- Tindall uses a sophisticated production scheduling procedure. This is needed because usually there are several different precast projects being manufactured at the same time.

- To coordinate and schedule the work of their project, the Project Manager (PM) must first become familiar with the number and types of precast members that will be required for the job. From there, the PM will work with Production Planning to identify the number and types of forms that will be needed to manufacture the members.

- Tindall’s PM stays in close contact with the progress of the GC’s site work to ensure the site will be ready when the precast is delivered.

This description could go on and on, but perhaps a significantly simplified Gantt chart would be more helpful. One such is shown below. Since precast piece production can start before the site and foundation work is completed, the time between the start of precast production and the end of the foundation work is the major opportunity for time savings, thus speed.

Once a sufficient number of precast members are fabricated to ensure installation cannot overtake production, erection of the members can begin onsite. There are a couple of numbers that are key to the duration and speed of precast concrete installation. The most important is the total number of individual precast pieces – called piece count. Another important number is the average number of pieces that can be erected per day. This number will vary depending on the complexity of the installation and will also vary day-to-day.

For a project with intricate architectural pieces that, for example, include brick inlay and reveals which must be carefully aligned, perhaps only 6 to 8 pieces can be placed per day. For a simple parking deck with repetitive parts like double tees, the daily erected count may be 15 to 20 pieces. The combination of the two numbers, piece count and pieces erected per day, determines the speed/duration of installation.

Another key to expediting a precast concrete project is having an efficient access plan for the delivery of precast members and the movement of the job’s crane. If delivery trucks are required to pull in and back out of the site using one access point, daily piece counts can drop significantly. Tindall’s project managers and field service representatives can work with the GC’s field personnel to optimize crane and truck flow to ensure a steady flow of deliveries and a continual supply of product to the crane.

Structural Layout Implications for Speed

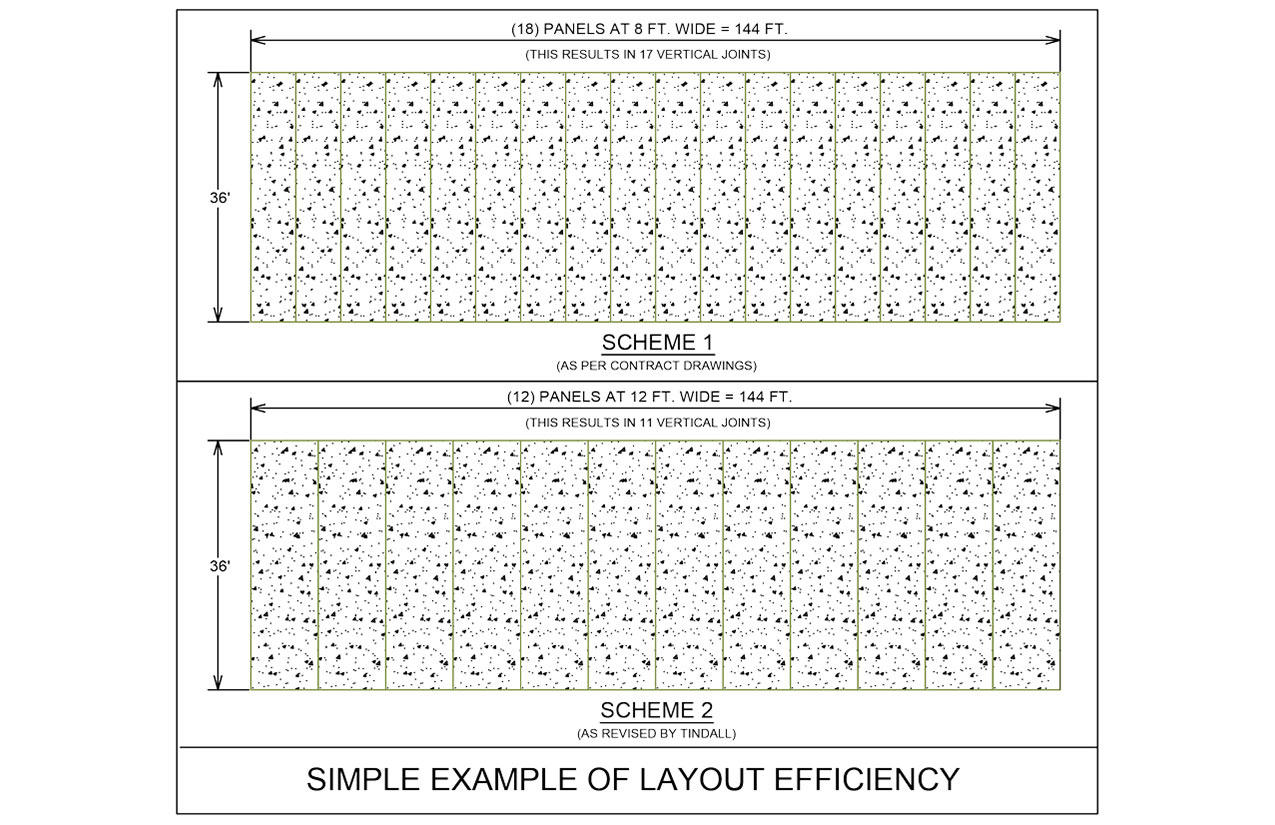

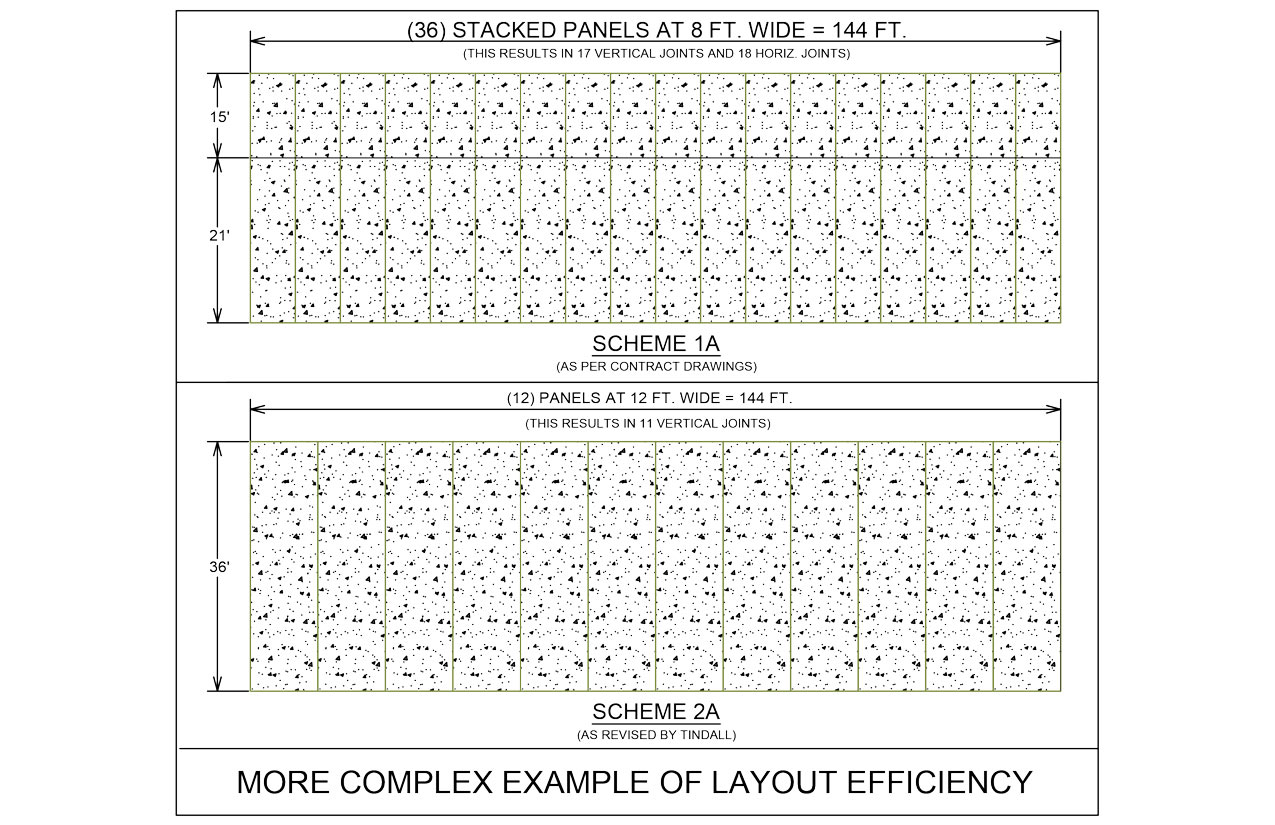

How a structure is conceived and laid out is an essential aspect concerning the speed and efficiency of precast construction. Below are two examples of layout efficiency. One is a simple example of this concept when applied to a wall panel elevation, and the other is a more complex example, which turns thirty-six panels into only twelve panels. Using creative layouts, Tindall can save the time needed for precast installation. Of course, any changes to the contract drawing layout must be coordinated with and approved by the project architect and structural engineer.

The first saving is realized by fewer joints and linear feet of caulking that must be used for the original layouts. The second and most impactful result is the fewer individual pieces that must be used. Each time a precast piece is touched (stripping, storage, loading, transporting, installation), there is a time duration involved. In terms of crane time, the longest of these is installation. The time for installing a 12’ x 36’ wall panel is similar to installing an 8’ x 18’ wall panel. The bottom line is that the fewer pieces used, the shorter the total precast installation time. As demonstrated below, in the most extreme case, thirty-six panels are combined to make only twelve larger panels.

Using prestressing in the pieces allows for the manufacture of larger pieces. As previously mentioned, the fewer the pieces, the faster the production and erection.

Tindall’s Methods for Sustaining Safety and Quality While Maintaining Speed

As previously mentioned, safety and quality are the two top priorities in Tindall’s culture. These two items must never be sacrificed for any reason, including the desire for speed. How can this be accomplished? Two familiar words come to mind again – efficiency and practicality.

Efficiency is obtained by carefully studying and analyzing all aspects of work needed to complete a precast concrete project. One tool used to accomplish this is the development of practical work processes and procedures. To create these procedures, Tindall has over 25 Industrial Engineers (IEs) on staff. Tindall is the industry leader with this large commitment to process evaluation and development. The IEs conduct numerous time studies for each work task. They collaborate closely with the individuals who do these tasks and then develop a detailed procedure for each task. While developing the processes, safety and quality remain the top priorities. Once developed and followed, these procedures create a safe and efficient method for completing various tasks while maintaining quality.

To better serve their clients and to help their employees grow and advance, Tindall constantly brings in industry-leading consultants to conduct training in the most advanced and current practices in the various disciplines.

Summary

Precast concrete construction is a fast and efficient method of construction. Tindall uses various tools along with professional and resolute staff to assist their customers in achieving a high-quality project in the least amount of time while maintaining a safe work environment in the precast facility and on the project site. The sooner Tindall is invited to participate in a project and become a part of the project team, the more assistance Tindall can provide and help accomplish a successful, efficient, and fast-moving project. Get in touch with us today.