A common belief held by the general public and many architectural and engineering professionals is that precast concrete is an “off-the-shelf” commodity-type product, very similar to the lumber yard concept. In other words, the belief is that the precast manufacturer makes a quantity of double tees, beams, columns, floor slabs, etc., and stockpiles them for purchase and use. This is not the case for precast components used in building structures, especially for Tindall Building Systems.

Explaining the Tindall Approach to Overall Project Design and Engineering

Each project has needs and requirements that are unique to that project. If the project is located in a high seismic area or a coastal location with high wind forces or in a low seismic, low wind area, the demands on the structure are very different. If the project has very large floor/roof loads vs. a parking deck load or warehouse load, the size and strength of the precast members vary greatly. Consequently, the members and connections required for each project differ. Sometimes, even within a certain project, the member size may be the same, but the member strength demands differ. An example would be a parking structure where the top-level loads are greater due to snow loads than the floor loads that have no snow load. The roof and floor member sizes and cross sections may be the same, but the internal prestressing and reinforcing for the roof members will be greater than that of the floor members.

Consequently, the types, sizes, and reinforcing of members are uniquely designed for each project. The connection concepts and design are also custom-configured for each project. Not only is the structural design important, but the overall aesthetics of the building must also be considered and accommodated. Additionally, the layout must be coordinated with equipment locations, exit requirements, clear height needs, desired open-floor spaces, etc.

Satisfying all of these conditions is a challenge. To accomplish this task, Tindall has a large engineering staff (over 100 graduate engineers) and a project coordination staff that works closely with the project team consisting of the owner’s representatives, project architects, project engineers, the selected general contractor, and others as needed.

The Project Design Efforts and Responsibilities of Tindall Explained

Since each project is unique, Tindall’s design efforts and responsibilities vary. The usual first thought is what structural components and connections are needed. There are other concerns, but the project scope usually begins with the structural aspects of the project.

Once the design team has determined the basic building layout concerning the floor plan and building facades, the design of the structure can begin. So, who does what? Typically, Tindall will have the design responsibility of the precast structure located above the foundations. Tindall engineers will communicate to the foundation engineer all of the loads the precast structure applies to each foundation. This is important so that the foundation, precast design, and components are in harmony.

Other very important considerations are the interfaces and relationships between the precast structure and other building components, such as:

- windows

- doors

- equipment support

- masonry walls

- reinforced concrete retaining walls

- elevator equipment and more

Following one of Tindall’s tenets, “Engineered to Serve,” the Tindall staff works closely with the owner and their design professionals to address each unique aspect of their project.

How Tindall’s Project Team Collaborates with Design Professionals to Meet and Exceed the Project Requirements

The best way for a Project Owner and their design professionals to get the “best bang for their buck” and have a successful project is to bring Tindall design-assist resources into the project team as soon as possible. Tindall has created a staff of professionals that can creatively and positively help create a building strategy that will foster a successful project.

Typically, a project has several design phases. The very first is that the owner has an idea of what they need and when they need it for their business. The owner will usually then discuss their idea with an architect, who will sketch out a concept of the building. Then other engineers, such as those working on structural, mechanical, and electrical systems, will be consulted to further add to the building concept. This initial effort is called the Conceptual Design Stage. It is either during or shortly after the initial concept is done that it is time to bring Tindall into the team. Several of precast concrete’s distinct advantages are speed of construction, structural efficiency (i.e., cost), and sustainable building practices. Because Tindall produces standardized member shapes on reusable steel forms, it can generate large numbers of pieces on a daily basis with minimal forming waste. In order to take optimal advantage of this approach, Tindall engineers will strive to create layouts that make maximum use of these standardized shapes and details. Introducing this analysis into the design phases as early as possible will bring maximum benefit to the project.

The next project phase is called Preliminary Design. During this phase, the project is further developed, and more detail is added. The last design stage is Final Design. During this phase, the structure, its connections, and details are finalized and drawn in preparation for fabrication and installation of the precast members.

Tindall has made a strong commitment to create and develop a qualified staff of project managers and engineers, capable of providing the needed expertise and resource to assist in the project’s custom design. Each Tindall location has dedicated project management and engineering staff capable of assisting outside design professionals. In addition, Tindall has a Corporate Engineering Office and an Engineering Product & Systems Development Group that further enhance and strengthen project development and success.

Some examples of how the Tindall team has creatively impacted and helped owners and professionals achieve successful projects are described below.

DOW Chemical Projects

Tindall has teamed up with DOW Chemical Company on several industrial projects in recent years. The project named DOW Poly 6 will be highlighted here. DOW had a long history of using cast-in-place concrete (CIP) construction on its projects, but in the case of Poly 6, reached out to Tindall to explore the potential use of precast concrete.

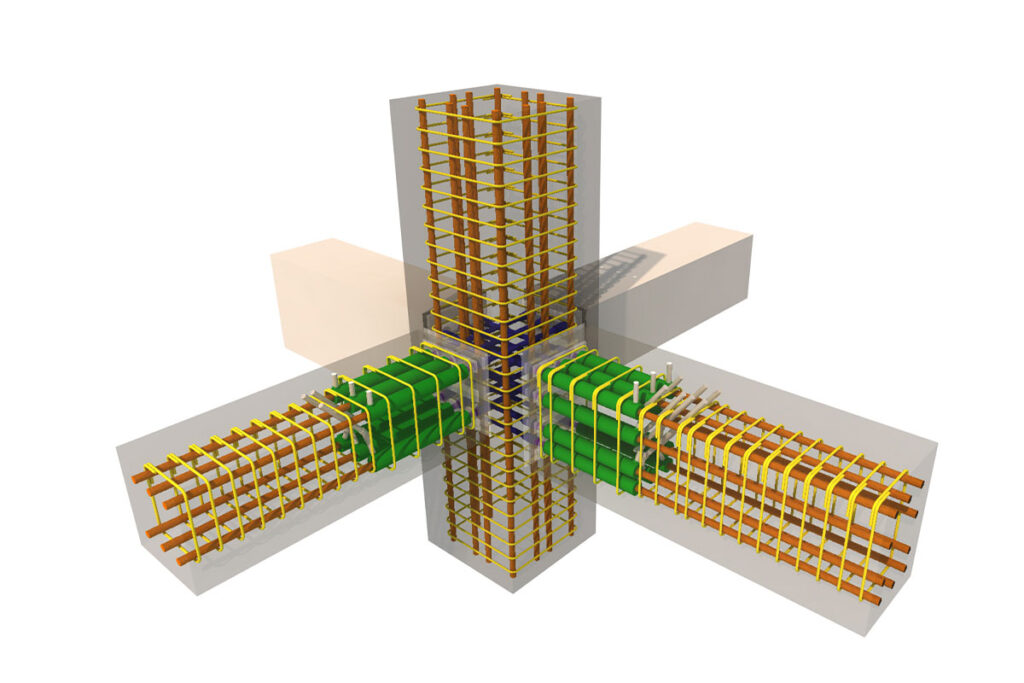

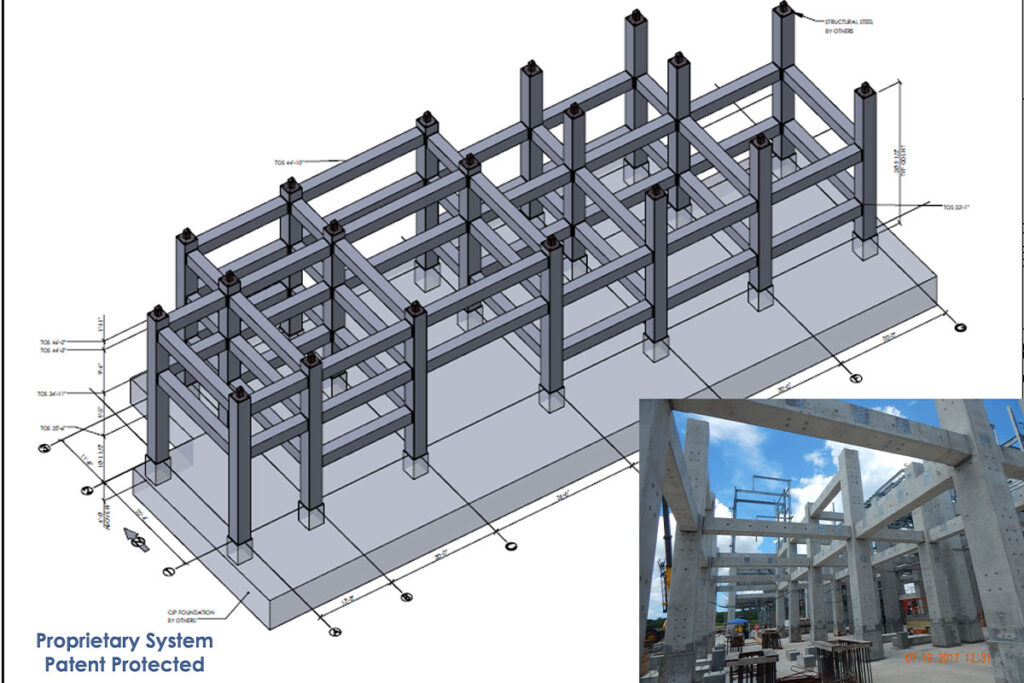

Poly 6 involved an elevated structure that supports many pipe runs, various equipment, and other items involved in different manufacturing processes. All of the processes required a strong structure that had limited projections, which could interfere with needed process items such as piping and equipment. To meet this challenge, Tindall’s Engineering Product & Systems Development Group (EPSD) developed a unique and creative rigid frame bent system. One of the keys to this system was the development of an innovative beam-to-column and beam-to-beam connection system. This connection, known as the ABC Connection, is proprietary and patented.

The ABC Connection includes splice sleeves and dowels to make a rigid connection between precast members. There are no permanent supporting corbels needed, thus creating a very clean detail.

To verify the adequacy and strength of this connection and frame concept, a mockup was built by Tindall and tested at Clemson University.

With the framing concept verified, approved, and accepted, the detailed structure layout and design commenced. At this time, Tindall’s Corporate Engineering team stepped to the front of the project-specific structural design and began configuring the structural frame for the project.

During the design phase, DOW asked if the top level of cross beams could be left off in order to facilitate the installation of various piping systems. Tindall analyzed this situation and confirmed this was possible. This allowed longer piping runs to be fabricated on the ground and then lifted into place. All pipe splice welds are full penetration welds that must be fully inspected. By being able to accomplish this on the ground, it saved a large amount of cost and time. Also, since no shoring was needed (as with CIP), the site access was generous and much safer for the workers.

The conversion of this project from CIP to precast saved a large amount of time and money. Three process structures involving over 200 pieces were erected in just two weeks. Part of the success of this and other DOW projects was due to Tindall’s on-site help and expertise at the beginning of construction.

Take a closer look at the DOW Poly 6 project.

Liberty University East Campus Parking Garage

In 2019, Liberty University’s football program was promoted to the top level of NCAA competition and became a full FBS member. As part of this transition, Liberty desperately needed additional parking capacity. They turned to Tindall to help address this issue and meet a very tight schedule.

The project had several challenges. The parking structure was to be located on campus and built while classes were active. This required all site work and deliveries to be coordinated so as to minimize disruption to classes and safely account for student pedestrians and travel. Additionally, the project site was significantly sloped, and truck access was limited.

To address the traffic challenges, Tindall’s project management team met with university officials very early in the project. To satisfy Liberty’s concerns, Tindall conducted test shipments along the projected delivery route, which had some narrow roads and very tight turns. The test runs were successful, and that problem had been solved.

Another Liberty requirement was to accommodate the incorporation of an administration building that existed on the project site. Tindall was able to integrate a new structure into the project using its proprietary T-SLAB product, creating a new administrative building in conjunction with the parking structure.

Tindall’s design team also contributed to the project by engineering an access route from the street into the 3rd level of the parking deck. Working closely with the architect, Tindall engineers developed a custom-designed precast bridge from the street to the parking deck to provide vehicular access.

Gibbs Cancer Center & Research Institute Expansion

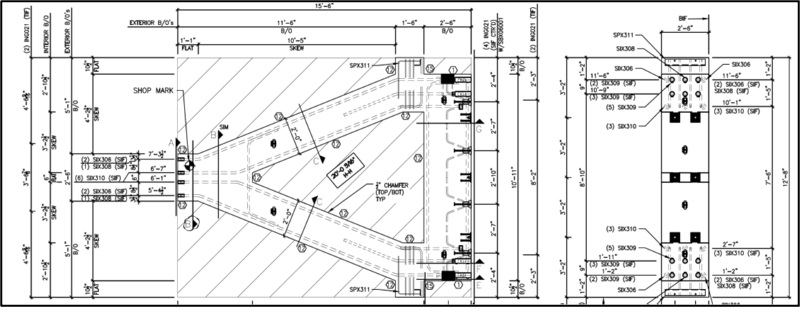

Precast concrete products were used in various aspects of this project, but the biggest challenge presented to Tindall was the pedestrian bridge needed to connect the existing administrative building with the new expansion. This bridge has a “dogleg” shape when viewed from above and the architect had highlighted the bridge by using Y-shaped columns to support the structure.

Through its coordination with the general contractor, Tindall proposed a conversion of the bridge from CIP to precast construction. This was a challenge, but Tindall approached it head-on and was able to engineer precast Y-shaped columns that met the architect’s design and aesthetic intent. Below is a sample production drawing of a Y-shaped column and a picture of the final product.

Because of the success in converting the pedestrian bridge to precast, the project team asked Tindall to value engineer the main building façade. The original design was to use field-applied brick. Tindall was able to convert this into tinted, sandblasted architectural precast wall panels. This saved considerable cost and reduced the time needed for completion of the structure.

Learn more about the Gibbs Cancer Center project.